This use case is intended to show you how to place a physical part from a reference part.

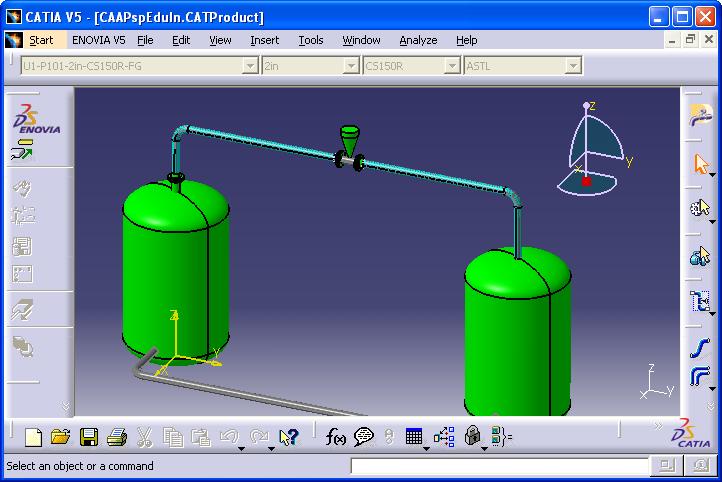

This macro opens the document CAAPspEduIn.CATProduct. Using the root node of the document, it then finds a piping valve and uses its reference to place another valve.

CAAPspPlacePart is launched in CATIA [1]. No open document is needed.

CAAPspPlacePart.CATScript is located in the CAAScdPspUseCases module. Execute macro (windows only).

CAAPspPlacePart includes the following steps:

Setup Environment

The macro first loads Distributive System document CAAPspEduIn.CATProduct containing Equipment and Piping Design objects.

Note: To open a different document, modify the variable sDocPath to point to the directory and sDocFullPath to point to full path name of the document.

... ' ------------------------------------------------------------------------- ' Setup the Environment ' ------------------------------------------------------------------------- ' Open the Distributive system document dim sDocPath As String dim sDocFullPath As String sDocPath=CATIA.SystemService.Environ("CATDocView") If (Not CATIA.FileSystem.FolderExists(sDocPath)) Then Err.Raise 9999,sDocPath,"No Doc Path Defined" End If sDocFullPath = CATIA.FileSystem.ConcatenatePaths(sDocPath, _ "online\CAAScdPspUseCases\samples\CAAPspEduIn.CATProduct" ) Set gObjPspDoc = CATIA.Documents.Open(sDocFullPath) If (gObjPspDoc Is Nothing) Then Err.Raise 9999,sDocPath,"No Document Open" End If ShowTraceOutputLine "Output traces from CAAPspPlacePart.CATScript" ...

Next, the macro acquires the gObjPspWorkbench object from the document using the top node of the object tree in a Distributive System document..

... ' Find the top node of the Distributive System object tree - . Set gObjPrdRoot = gObjPspDoc.Product If (gObjPrdRoot Is Nothing) Then Err.Raise 9999,sDocPath,"Unable to get root product object" End If Set gObjPspWorkbench = gObjPrdRoot.GetTechnologicalObject ("PspWorkbench") If (gObjPspWorkbench Is Nothing) Then Err.Raise 9999,sDocPath,"Unable to get PspWorkbench" End If ShowTraceOutputLine "Success in getting PspWorkbench" Set gObjRootProduct = gObjPspWorkbench.GetInterface("CATIAProduct", gObjPrdRoot ) If (gObjRootProduct Is Nothing) Then Err.Raise 9999,sDocPath,"Unable to get root product" End If ...

Next, the macro acquires the objPspApplication object corresponding to Piping application and initializes the application data.

... ' Get Application Set objPspApplication = gObjPspWorkbench.GetApplication(catPspIDLCATPiping) If (objPspApplication Is Nothing) Then Err.Raise 9999,sDocPath,"Unable to get PspApplication" End If ShowTraceOutputLine "Success in getthing objPspApplication" objPspApplication.Initialization() ...

Get Data for Part Placement

The first data the macro acquires for part placement is a PspTempListFactory object gObjListFactory on the application object. This is used to later generate lists of real values needed for part placement input

... '----------------------------------------------------------------------- ' Get Data for Part Placement '----------------------------------------------------------------------- ' Get gObjListFactory Set gObjListFactory = gObjPspWorkbench.GetInterface("CATIAPspTempListFactory", objPspApplication ) If (gObjListFactory Is Nothing) Then Err.Raise 9999,sDocPath,"Unable to get list factory" End If ...

Next, the macro uses the root product object gObjRootProduct to find a parent for the part to be placed.

... ' Get root product children and parent product for placed part Dim ParentProductRef As CATIABase Set ParentProductRef = Nothing Dim ParentProduct As Product Set ParentProduct = Nothing ShowTraceOutputLine "Number of root children = " & gObjRootProduct.Products.Count Dim Prod As CATIABase For Each Prod in gObjRootProduct.Products ShowTraceOutputLine "Root child product name = " & Prod.Name If (Prod.Name = "CAAPsp3DEduIn.1") Then Set ParentProductRef = gObjPspWorkbench.GetInterface("CATIABase", Prod ) Set ParentProduct = gObjPspWorkbench.GetInterface("CATIAProduct", Prod ) End If Next If (ParentProductRef Is Nothing Or ParentProduct Is Nothing) Then Err.Raise 9999,sDocPath,"Unable to get parent product" End If ShowTraceOutputLine "Part place parent product name = " & ParentProductRef.Name ...

Now the PspAppFactory object objPspAppFactory is used to search for a physical product that will serve as a reference for the part to be placed. In this case it finds a piping valve.

... ' Get PspPhysicalProduct object Dim objLPhysicals As PspListOfObjects Set objPspAppFactory = gObjPspWorkbench.GetInterface("CATIAPspAppFactory", objPspApplication ) Set objLPhysicals = objPspAppFactory.ListPhysicals ( gObjPrdRoot , catPspIDLCATPIP) If ( Not ( objLPhysicals Is Nothing ) And _ ( objLPhysicals.Count > 0 ) ) Then Set objPspPhysicalPrd = objLPhysicals.Item( 1, "CATIAPspPhysicalProduct" ) End If If (objPspPhysicalPrd Is Nothing) Then Err.Raise 9999,sDocPath,"Unable to get physcial part for reference product input" End If ShowObjectID "Physical Product object", objPspPhysicalPrd ...

Now the reference of the physical part (the valve) is found. A reference is needed as input to the part placement method.

... ' Get object reference part and parent. Dim objPhysicalProduct As Product Dim objReferenceProduct As Product Dim objParentProduct As Product Set objPhysicalProduct = gObjPspWorkbench.GetInterface("CATIAProduct", objPspPhysicalPrd ) If ( Not (objPhysicalProduct Is Nothing) ) Then Set objReferenceProduct = objPhysicalProduct.ReferenceProduct 'Just for info: got parent for part place above. Set objParentProduct = objPhysicalProduct.Parent If (Not (objParentProduct Is Nothing)) Then ShowTraceOutputLine "Parent part name = " & objParentProduct.Name End If End If If (objReferenceProduct Is Nothing) Then Err.Raise 9999,sDocPath,"Unable to get reference product input" End If ShowTraceOutputLine "Reference part number = " & objReferenceProduct.PartNumber ShowObjectID "Reference Product object", objReferenceProduct ...

The next piece of data needed is a logical line to contain the placed part. The macro uses the logical line that contains the valve already in the model. Note that the physical part can be in many groups: the code must filter for the group which is a logical line.

... ' Get logical line Dim LogicalLine As PspLogicalLine Set LogicalLine = Nothing Dim PhysicalProductGroupable As PspGroupable Set PhysicalProductGroupable = Nothing Set PhysicalProductGroupable = gObjPspWorkbench.GetInterface("CATIAPspGroupable", objPspPhysicalPrd ) If ( Not ( PhysicalProductGroupable Is Nothing ) ) Then ShowTraceOutputLine "Number of groups = " & PhysicalProductGroupable.Groups.Count Dim iiGroup As Integer For iiGroup = 1 to PhysicalProductGroupable.Groups.Count Dim Group As CATIABase Set Group = PhysicalProductGroupable.Groups.Item(iiGroup, "CATIABase") ShowTraceOutputLine "Group name = " & Group.Name Set LogicalLine = gObjPspWorkbench.GetInterface("CATIAPspLogicalLine", Group ) If ( Not ( LogicalLine Is Nothing ) ) Then ShowTraceOutputLine "Part place logical line name = " & LogicalLine.Name Exit For End If Next End If ...

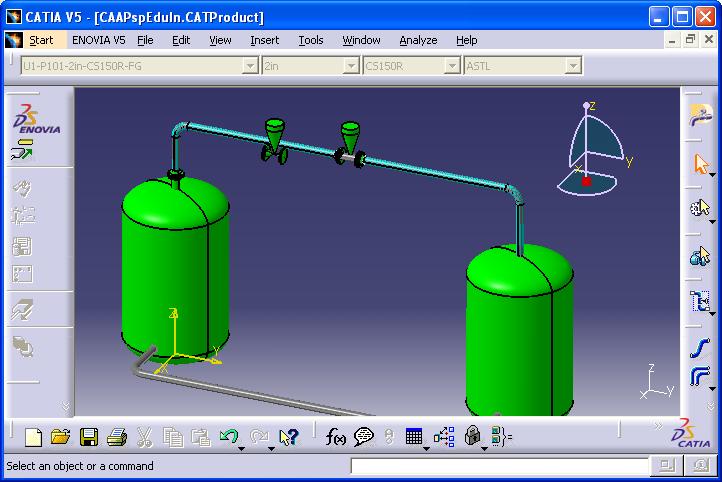

Place Part

Now enough data has been gathered to place the part. The placement is done by calling the PlacePartInSpace method on the objPlacePart object. Before PlacePartInSpace is called a few input argument values are set. Standard is set to specify the standard to be used in the placement. The function type to assciate with the placed part is specified by FunctionType. UpDirection, HorizontalOrientation and Position are set to properly position and orient the part. These are all taken by the PlacePartInSpace method as relative to the parent product.

... '----------------------------------------------------------------------- ' Place Part '----------------------------------------------------------------------- Dim Standard As String Standard = "ASTL" Dim FunctionType As String FunctionType = "CATPspValveFunction" Dim PlacedPartID As String PlacedPartID = "" 'Null string uses name generated by PP engine ' Up direction for part = (0,0,1) Dim UpDirection As PspListOfDoubles Set UpDirection = gObjListFactory.CreateListOfDoubles() UpDirection.Append 0.0 'Align vertical parallel to z-axis. UpDirection.Append 0.0 UpDirection.Append 1.0 ' Horizontal alignment for part = (1,0,0) Dim HorizontalOrientation As PspListOfDoubles Set HorizontalOrientation = gObjListFactory.CreateListOfDoubles() HorizontalOrientation.Append 1.0 'Align horizontal parallel to x-axis. HorizontalOrientation.Append 0.0 HorizontalOrientation.Append 0.0 ' Part position = (1000,2000,4000) (mm) Dim Position As PspListOfDoubles Set Position = gObjListFactory.CreateListOfDoubles() Position.Append 1000.0 'Position part at (1000, 2000, 3000) Position.Append 2000.0 Position.Append 4000.0 Dim PlacePartRef As CATIABase Set PlacePartRef = Nothing Dim objPlacePart As PspPlacePart Set objPlacePart = Nothing Set objPlacePart = gObjPspWorkbench.GetInterface("CATIAPspPlacePart", objPspApplication ) If ( Not ( objPlacePart Is Nothing ) ) Then Set PlacePartRef = objPlacePart.PlacePartInSpace(Standard, _ FunctionType, _ objReferenceProduct, _ ParentProductRef, _ LogicalLine, _ PlacedPartID, _ UpDirection, _ HorizontalOrientation, _ Position) End If If ( PlacePartRef Is Nothing ) Then Err.Raise 9999,sDocPath,"Place part error = " & objPlacePart.ErrorMessage Else ShowObjectID "Placed part", PlacePartRef End If ...

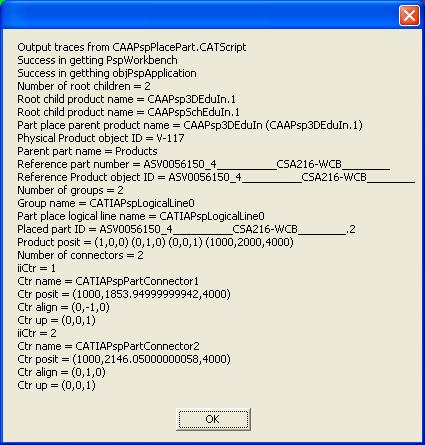

View and Test Part Data

After the part is placed, the script test and displays some data related to the placed part. First the position of the part itself is examined.

... '----------------------------------------------------------------------- ' View and Test Part Data '----------------------------------------------------------------------- ' Placed part position Dim objPlacePartProduct As Product 'Set objPlacePartProduct = PlacePartRef Set objPlacePartProduct = gObjPspWorkbench.GetInterface("CATIAProduct", PlacePartRef ) If ( objPlacePartProduct Is Nothing ) Then Err.Raise 9999,sDocPath,"Bad placed product" End If Dim placePartPositArray(12) As CATSafeArray objPlacePartProduct.Position.GetComponents(placePartPositArray) ShowTraceOutputLine "Product posit = " & DumpTransform(placePartPositArray) ...

Finally data associated with the part connectors of the part is tested and displayed.

... ' Placed part connectors Dim objPlacePartPhysical As CATIAPspPhysicalProduct Set objPlacePartPhysical = Nothing Set objPlacePartPhysical = gObjPspWorkbench.GetInterface("CATIAPspPhysicalProduct", PlacePartRef ) If ( Not ( objPlacePartPhysical Is Nothing ) ) Then ShowTraceOutputLine "Number of connectors = " & objPlacePartPhysical.Connectors.Count If ( objPlacePartPhysical.Connectors.Count <> 2 ) Then Err.Raise 9999,sDocPath,"Wrong number of connectors" End If Dim iiCtr As Integer For iiCtr = 1 to objPlacePartPhysical.Connectors.Count ShowTraceOutputLine "iiCtr = " & iiCtr Dim Ctr As PspPartConnector Set Ctr = objPlacePartPhysical.Connectors.Item(iiCtr, "CATIAPspPartConnector") If ( Ctr Is Nothing ) Then Err.Raise 9999,sDocPath,"Bad connector" End If ShowTraceOutputLine "Ctr name = " & Ctr.Name Dim CtrPosit As PspListOfDoubles Set CtrPosit = Nothing Set CtrPosit = Ctr.GetPosition(ParentProduct) ShowTraceOutputLine "Ctr posit = " & DumpVector(CtrPosit) Dim CtrAlign As PspListOfDoubles Set CtrAlign = Nothing Set CtrAlign = Ctr.GetAlignmentDirection(ParentProduct) ShowTraceOutputLine "Ctr align = " & DumpVector(CtrAlign) Dim CtrUp As PspListOfDoubles Set CtrUp = Nothing Set CtrUp = Ctr.GetUpDirection(ParentProduct) ShowTraceOutputLine "Ctr up = " & DumpVector(CtrUp) Next End If ...